BOX/GAYLORD FEEDER

BOX/GAYLORD FEEDER

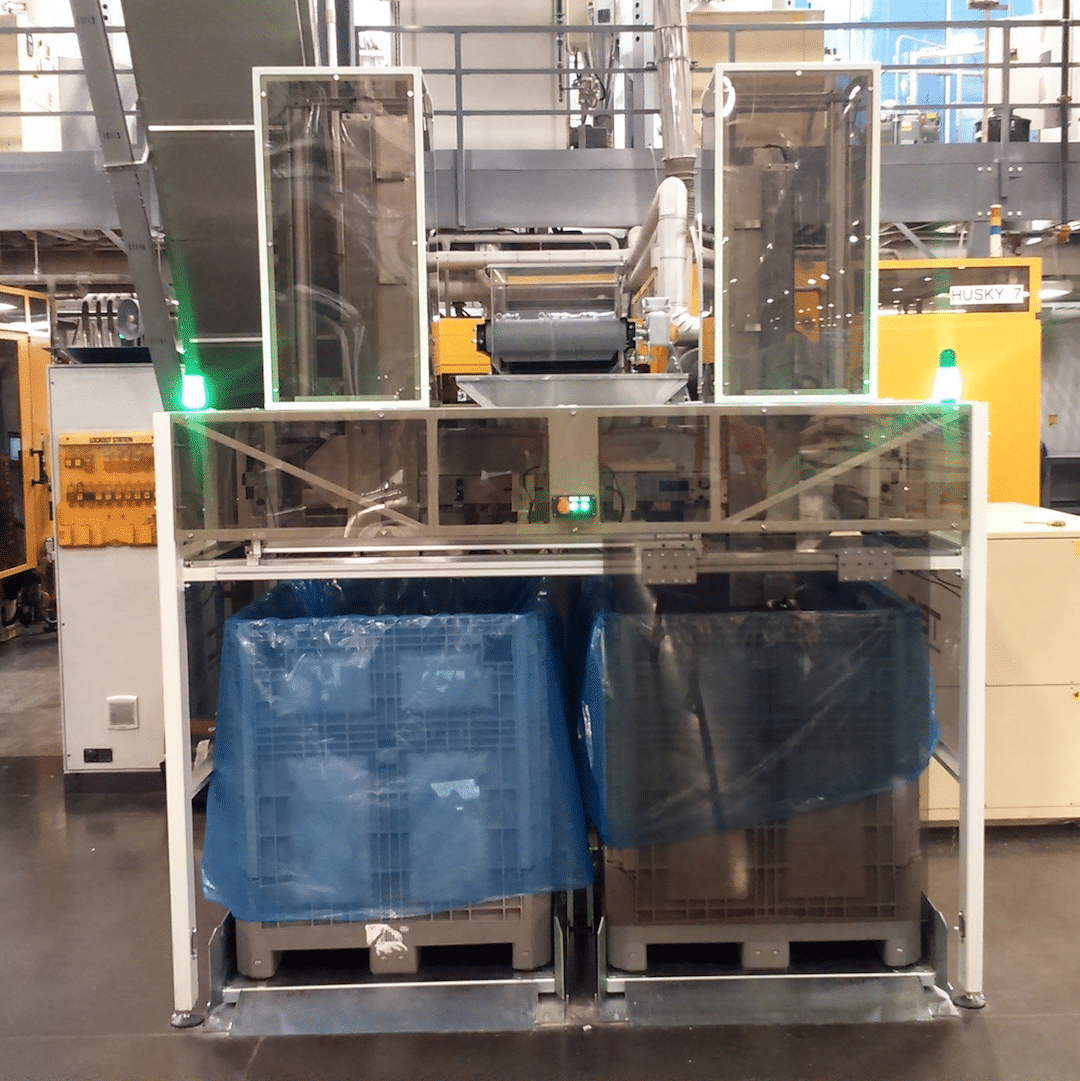

SOFT DROP TOTE FILLING

The soft drop filling system allows to minimize the damages on the plastic preforms when they are being packaged. It alternates between two totes, lowering the plastic parts down to the fill level inside the box.

- Vibrating Base to maximize Gaylord capacity.

- Ionizer to eliminate static charge and avoid dust accumulation on the preforms.

- Cooling module to allow for faster injection cycles.

- Gentle handling option to load gaylords with a max drop of 6″.

- Bi-directional conveyor to fill two gaylords.

BI-DIRECTIONAL TOTE FILLING SYSTEM

Our Tote and Gaylord Filling Systems allow Totes and Gaylord filling with a precise amount of preform. The preset quantity of perform is determined by the injection machine cycles.

BENEFITS

- Automatic repositioning to empty container.

- Fills containers to a preset number of machine cycles.

- Designed for maximum product containment.

- High volume transfer capability.

- Fully programmable PLC controller.

COMPONENTS

The filling system is composed of three main elements:

a) Inclined Conveyor: To receive injected preform and lift it so it can be feed into the storage containers.

b) Two Way Diverter: To allow the continuous filling of two containers, side by side.

c) Control Panel: To count and control the amount of preform being fed into the storage containers and two automatically switch to empty container once the first is full.