AIR CONVEYOR SYSTEM

AIR CONVEYOR SYSTEM

THE SYSTEMS

INTEC SOLUTIONS offers entire Air Conveyor Systems for PET and HDPE bottle containers. We design and manufacture the parts to install on your production line, as well as prepare the recipes for your blower speed management programs.

Our standard systems are build for high speed performance and lightweight bottles. They are energy efficient, modular and durable in order to adapt to any future changes on the production plant.

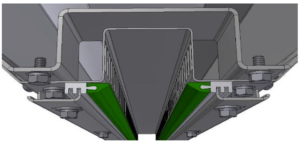

Low Friction Neck Guide

The green neck guide has an original recipe to make it the material with the lowest friction in the market, having minimum contact with the bottles and a smoother transportation along the Air Conveyor. The neck guide has proven to increase efficiency as much as 20% by lowering energy consumption, decreasing bottle jams, and speeding up the change over times during maintenance.

Universal CAM Side Guide

The CAM System is designed to fit 95% of the bottles in the market, and it can be customized to fit your particular range of bottle sizes, while allowing room to integrate new ones in the future. It uses one level of side guide directed by a linear electric actuator, which reduces the cost of air used to run pneumatic pistons and also the issues that arise from fluctuating of air pressure.

Advantages:

- Multi-format XY side guide

- Just ONE level of side guide to run all your bottles

- Perfect change-over system

- Easy Maintenance

- Overall Cost Savings on Labor and Energy

NECK GUIDE

The green neck guide has an original recipe to make it the material with the lowest friction in the market, having minimum contact with the bottles and a smoother transportation along the Air Conveyor. The neck guide has proven to increase efficiency as much as 20% by lowering energy consumption, decreasing bottle jams, and speeding up the change over times during maintenance.

UNIVERSAL CAM SIDE GUIDE

The CAM System is designed to fit 95% of the bottles in the market, and it can be customized to fit your particular range of bottle sizes, while allowing room to integrate new ones in the future. It uses one level of side guide directed by a linear electric actuator, which reduces the cost of air used to run pneumatic pistons and also the issues that arise from fluctuating of air pressure.

SERVICES

INTEC SOLUTIONS offers a wide range of services for your Air Conveyors to improve the complete production line efficiency. Our services range from complete new line (studies, design, integration, production, installation, and commissioning) but also perform project management, for maintenance, line relocations, retrofits and reprogramming.

The service on the lines are based on an audit and diagnostic, which can be performed in stages and for any conveyor brand in the market.

We specialize in: