INNOVATION TECHNOLOGY

PREFORM SILO

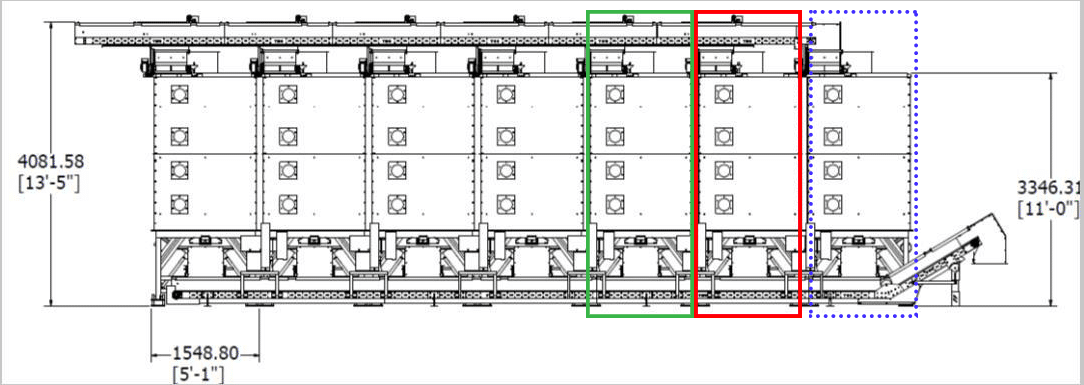

The operation of the Silo storage system is designed to run preforms from injection machine(s) to a silo(s) for storage, to later be distributed to one or several production lines through a multiplex system.

Each module is built as a full enclosed stainless steel silo with a capacity of 8 full size gaylords (capacity = 240 ft3). They are equipped with internal static and dynamic pressure protection to assure zero defects.

BENEFITS

- Automated buffer in-feed preform sampling for QC.

- Automated handling of quarantine lots.

- Automated handling of scrap preform to grinder.

- Communication with Material Requirement Planning (MRP).

- Automated inventory reporting.

- Reduction of Acetaldehyde.

- Dynamic pressure control design.

- Static pressure control design.

The system guarantees First In First Out (FIFO) operation with product traceability.Optionally a module can be placed in quarantine for later delivery to the blow molder or rejected to be sent to the preform grinder automatically.

ACETALDEHYDE (AA)

What is AA?

Is a degradation by-product formed when PET is melted. The presence AA in the PET wall can contaminate beverages and alter their taste.

PET resins meet the requirement for packaging strongly flavored drinks such as colas (<8 ppm of AA in the preforms). But the most stringent application is the packaging of drinking water, preforms with less than 3 ppm of AA are required.

The only sure method to reduce AA in PET preforms is aging.

How we reduce it?

- Preform buffer with forced HEPA filtered air flow.

- Reduces Acetaldehyde levels from 8 ppm to 3 ppm in 20 hrs. or less.

AUTOMATED GUIDED VEHICLES (AGVs)

AUTOMATED CAM SIDEGUIDE